Everything about Grit Blasting

Wiki Article

Some Ideas on Harbor Freight Sand Blaster You Should Know

Table of ContentsRumored Buzz on Sand Blaster Harbor Freight4 Easy Facts About Portable Sandblaster ShownThe 4-Minute Rule for Sand Blasting SandAn Unbiased View of Shot Blasting Near MeIndicators on Black Diamond Blasting Sand You Should KnowFacts About Harbor Freight Sand Blaster Revealed

Economy and non-industrial sandblasters for residence or DIY use usually come with inexpensive steel nozzles. If you bang a boron carbide or silicon nitride nozzle into a component, grate, or closet wall, after that the nozzle is a lot more likely to fracture compared to a concrete tungsten carbide nozzle.The abrasive blasting process gets rid of the surface area contamination and converts it right into dust. The dirt and media are taken care of utilizing dirt collection agencies, industrial vacuums, and separators. Rough blasters can delicately remove graffiti, paints, as well as finishings without the removal of the base product - harbor freight sand blaster. The unpleasant gun can additionally deeply blast a steel surface area to completely eliminate any rust, range, or followers to a NACE/SSPC "white steel" cleanliness quality.

Next off, the surface area is peened with tiny spheres or microbeads to fine-tune the surface finish. If the part has a rough (high roughness standard, Ra) surface coating like an as-cast or as-forged surface, then peening can modestly refine the surface finish. If the component has actually been ground or machined to a smooth or low Ra surface, after that shot peening will certainly lead to a rougher surface area coating.

Some Ideas on Pressure Washer Sandblaster You Should Know

Layer, paints, and adhesives stick much better to a harsh surface contrasted to a smooth surface. An unpleasant blew up surface area produces a support profile with undercuts as well as more surface area for finishes and also adhesives to grab onto. A sandblast roughened surface on a stainless handrail aids individuals get a better hold too.

Rust and also deterioration layers require to be eliminated too, especially for safety coverings satisfying the National Association of Corrosion Engineers (NACE) and also Culture of Surface Protective Coating (SSPC) standards. Three reasons to remove corrosion or corrosion with abrasive blowing up are: Rust and also corrosion layers are weak and softer compared to the underlying metal.

An Unbiased View of Pressure Washer Sandblaster

A blast roughened surface area provides mechanical interlocking in between the layer and also substrate. No, since if a surface area is as well rough, then thinner safety coatings might not totally cover the surface resulting in pinholes and also rust of the underlying surface area. Shot, grain, and also unpleasant blasting can lower a few of the high heights in a surface area account to boost rust protective finishing efficiency.Medical/ Oral Cleaning, layer prep work, etching, and polishing of clinical devices and also oral reconstructions. For instance, the financial investment or mold and mildew material on cast crowns or bridges can be carefully removed with a small benchtop sandblaster or micro-blaster. Hip, shoulder, oral and also other bone, as well as joint implants are blast cleaned to satisfy strict FDA cleanliness demands.

Certain materials such as lead-based paints and also heavy steels produce hazardous or poisonous dust when blasted. Wet or water blowing up systems reduce the dust issue (sand blasting sand).

Indicators on Dustless Blasting Near Me You Need To Know

Media and palatable wear components need to be gaged to maintain consistency as well as after that fixed or changed at proper intervals to assure high quality as well as security. The price of media as well as consumables should be factored into your sandblast cupboard choice procedure. Sandblasters or sandblasting operators can be harmed during rough blowing up. The high-pressure unpleasant stream can damage skin as well as eyes.Soda, completely dry ice, and also damp blasting maintain components trendy during blasting. Abrasives as well as blast media can get lodged into crevices on a component and can be challenging to eliminate.

Validate the blowing up procedure criteria with an added examination or test. Estimate the annual operating and also palatable expenses such as pressed air, water, as well as electrical power intake. What are the palatable costs such as blast media, wear component replacements, and also system upkeep prices? What are the labor expenses and training demands? The number of published here drivers are called for to run the blast system? Is unique security and automation system training required? Send a quote for the sandblast cabinets along with any extra questions to clarify training as well as yearly approximated operating, maintenance, and also palatable expenses.

The Basic Principles Of Harbor Freight Sand Blaster

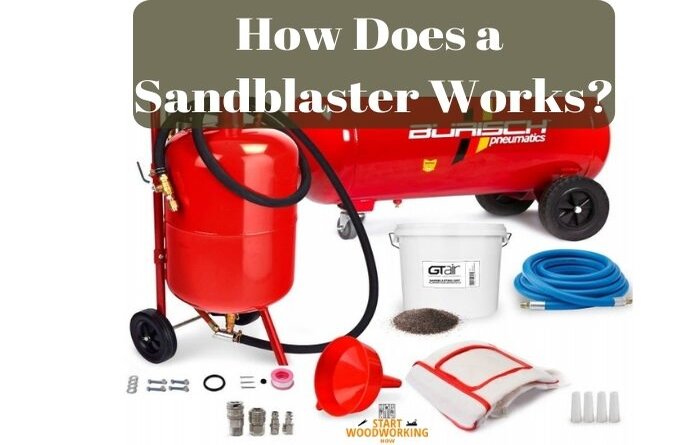

There are 3 basic parts to this design: an air compressor or pressurized air tank, a hand-held pressure gun with air hose pipe and also a receptacle on top of the gun. The hose pipe attaches to the air tank, and also the hopper is filled with silica sand.

They contain a huge container containing silica sand under high stress. This is a little bit comparable try these out to the concept behind an aerosol. A sandblasting gun, normally a two-handed design, is connected to the port on top of the cylinder using a specialized hose pipe that can endure the abrading affects of the sand.

What Does Black Diamond Blasting Sand Mean?

Report this wiki page